Introduction

The primary purpose of work control permits is to ensure that hazardous work is carried out safely, with appropriate controls in place to prevent accidents and injuries to people & assets, ideally for every physical activity performed in a place of work, that could cause injury or damage.

The permit to work (PTW) system, typically involves a detailed process for hazard identification, risk assessment, with all relevant information recorded, historically on paper proforma, referenced during the activity, and retained post as a record of what took place. The permit asks questions of those undertaking the work, asking those taking part in the work to describe the activity they are undertaking, how they will perform it, and to consider ways in which they can undertake the activity more safely. Often permits forms are specific to task type and contain clear procedures for workers to follow when carrying out a particular task.

By using a permit to work system, companies can reduce the risk of accidents, protect workers, the environment, and demonstrate compliance with their relevant country’s regulatory requirements.

Origins

The use of work control permits dates from the early 20th century when they were first introduced by the US Navy to ensure safety during ship repairs. The Navy recognized that certain types of work, such as hot work and welding, posed a significant safety risk and needed to be carefully controlled. As a result, the Navy developed a permit system that required workers to obtain permission before carrying out these types of work.

Over time, other industries also began to adopt permit to work systems, particularly those that involved hazardous work such as chemical and nuclear plants.

In the 1970s, the UK's Health and Safety Executive (HSE) introduced a permit to work system as part of its guidance on the Control of Major Accident Hazards (COMAH) regulations. This system required companies to obtain permits before carrying out certain types of work, and included detailed procedures for hazard identification, risk assessment, and permit issuance.

Industrial Accidents leading to further evolution of Permits

The development and implementation of PTW systems were further influenced by various incidents and accidents that highlighted the importance of managing risks associated with hazardous work, such as oil and gas, construction, mining, and manufacturing, where there is a high potential for accidents and hazards.

Major industrial accidents, such as the Flixborough disaster in the UK in 1974, and the Piper Alpha oil rig explosion in 1988, led to increased awareness of the need for stringent safety measures and improved control systems.

Initially, PTW systems were primarily paper-based, involving the issuance of physical paper permits to workers, authorising them to carry out specific tasks under controlled conditions. These permits are typically signed by authorised personnel, including supervisors, safety managers, and any relevant stakeholders.

The first digital permit to work (PTW) systems started emerging in the late 1990s and early 2000s with the advancement of computer technology and the widespread adoption of digital platforms in industries. While it's challenging to pinpoint the exact date of the first digital PTW system, here are a few notable digital PTW milestones:

1990s: In the late 1990s, computer-based permit to work systems began to be developed and implemented by some forward-thinking organisations. These systems typically utilised desktop or client-server applications that digitised the permit issuance and management process.

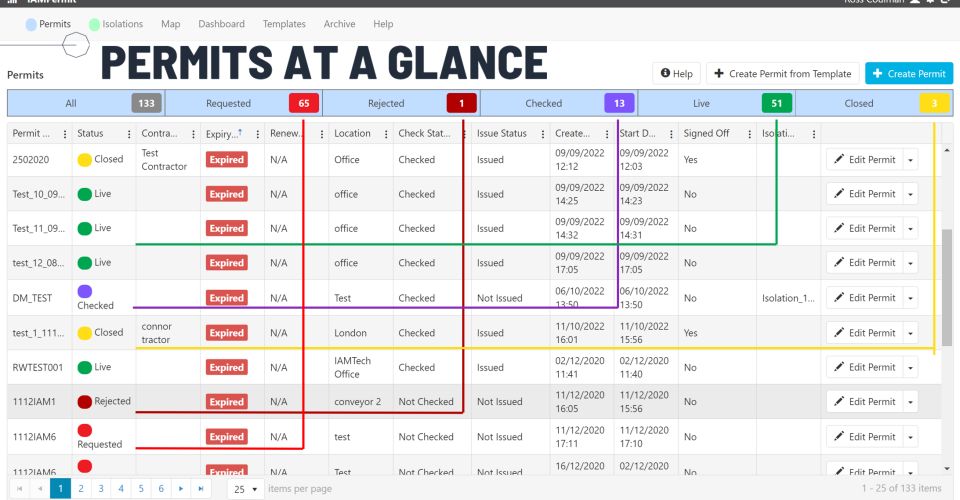

Early 2000s: As technology continued to advance, web based PTW systems started to appear. These systems allowed for online access to permit forms, centralised databases, and improved collaboration among different stakeholders involved in the PTW process, reducing the delay between request, checking, and issuing of permits, reducing non-productive time, e.g., the time maintenance workers are stood idle.

2010 onwards: By 2010, mobile devices such as tablets and smartphones became more prevalent, and PTW systems started leveraging mobile technology. Mobile applications and platforms were developed to enable on-site permit management, electronic signatures, and real-time data synchronization.

Present: With the advent of Internet of Things (IoT), and other digital advancements, PTW systems have become more sophisticated and integrated with other software systems in an organisation, such as an organisations ERP software, enabling permits and work orders to be linked.

In addition, digital PTW solutions offer features like automated workflows, data analytics, integration with other safety systems, and enhanced communication and reporting capabilities.

Global industrialization leads to acceleration of technology for Safety

The shift from paper based PTW systems to digital solutions has been a gradual process, however as developing nations catch up, we now have a greater global focus on workplace safety, and efforts are being made to enhance PTW systems worldwide. This has further accelerated technological advancements and the recognition of the benefits of digitization in improving safety, communication, and record-keeping in hazardous work environments.

Conclusion

The increased focus on workplace safety, along with technological advancements, has accelerated the adoption of digital PTW systems. Efforts are being made worldwide to enhance PTW systems, ensuring that they are robust, standardised, and effectively implemented across all industries and regions. Governments, regulatory bodies, and organisations are increasing their investment in safety management systems, training programs, and digital infrastructure to support the adoption of digital PTW solutions.

This collective focus on workplace safety and the adoption of digital PTW systems are contributing to a safer work environment and reducing the potential risks associated with hazardous work activities. As organisations continue to prioritise safety and governments strengthen regulatory frameworks, the future of PTW systems is expected to involve further advancements and integration with other software systems to enhance overall safety management!